2026 How to Choose the Best Texas Label Printers for Your Business Needs?

When selecting Texas label printers for your business, consider several important factors. The operating environment matters. Will the printers function effectively in your specific industry? Quality is crucial. Look for printers that produce clear, durable labels.

Also, evaluate speed and efficiency. You need printers that keep up with your demand. Texas label printers vary in features, so identifying your business’s unique needs is vital. Each option might come with strengths and weaknesses.

Cost can influence your choice as well. Assess your budget against the long-term value offered by different printers. A cheaper option might lack necessary features. In the end, choosing the right Texas label printers should empower your operations, not complicate them. Make informed decisions and reflect on what suits your business best.

Understanding Your Business Label Printing Needs

When selecting label printers for your business, understanding your specific needs is crucial. Different industries have unique requirements. For example, a food business may need waterproof labels. On the other hand, retail may focus on vibrant colors and designs. Analyze what type of labels you need. This can include size, stickiness, and durability.

Consider the volume of labels you print. If you need hundreds daily, invest in a high-capacity printer. Think about the printing speed, too. A slow printer can disrupt your workflow. Visualize your workspace: the printer should fit comfortably. It shouldn’t crowd your environment. Also, take time to research the options available. Many details could be overlooked, like user-friendliness.

Choosing the right label printer is not just about features. It’s also about your team’s comfort level with the equipment. A complicated printer can lead to frustration. Users may need extra training, potentially wasting time. Reflect on previous printing experiences. Learn from what worked and what didn’t. This will guide you in finding the perfect match for your business needs.

Evaluating Different Types of Label Printers in Texas

When evaluating different types of label printers in Texas, it's essential to consider several factors. Understanding what your business specifically needs is crucial. Various technologies dominate the market, including thermal transfer, direct thermal, and inkjet printers. Each type has distinct strengths and potential drawbacks. For instance, thermal transfer printers are ideal for durability and print longevity. However, they may not be suitable for high-resolution graphics.

A recent industry report showed that 45% of businesses prefer thermal label printers for their efficiency. Direct thermal printers, on the other hand, are favored for their simplicity and cost-effectiveness. Yet, they can be less reliable for outdoor use due to fading. Inkjet printers offer vibrant color options, but their maintenance can be demanding.

It’s not just about choosing the right technology; user experience matters too. Many companies find themselves overwhelmed by the variety available. User feedback highlights issues like confusing interfaces or slow print speeds. Making a choice should involve assessing both functionality and ease of use. Balancing these factors is critical for optimal investment.

Cost Analysis: Budgeting for Label Printing Equipment

When choosing the best Texas label printers, cost analysis plays a crucial role. Your budget determines the type of equipment and quality of labels you can produce. Consider not just the initial investment but also long-term costs like maintenance and supplies.

Tips: Always factor in potential expenses. Do not overlook the price of ink, labels, and servicing. These costs can add up quickly.

Research various options that match your business needs. Some printers might seem affordable but require expensive consumables. Think about how often you will print labels. If you have a high-volume requirement, a more robust printer might save you money over time.

Tips: Look for energy-efficient models. They can lower your utility bills significantly.

Investing in quality equipment can enhance your brand image, but remind yourself to stay within your budget. You may find cheaper options, but they could lead to hidden costs down the line. Reflect on what you truly need versus what looks appealing.

2026 How to Choose the Best Texas Label Printers for Your Business Needs? - Cost Analysis: Budgeting for Label Printing Equipment

| Printer Type | Average Cost ($) | Print Speed (Labels/Minute) | Resolution (DPI) | Ideal for |

|---|---|---|---|---|

| Thermal Transfer | $1,200 | 8 | 300 | Industry & Logistics |

| Inkjet | $800 | 6 | 1200 | Retail & Food Products |

| Laser Printer | $1,500 | 12 | 600 | Office & Shipping |

| Direct Thermal | $600 | 5 | 200 | Inventory & Shipping |

Key Features to Look for in Texas Label Printers

When choosing the right label printer in Texas, consider the print quality. Superior print resolution ensures clear and accurate labels. This is crucial for branding and readability. Look for printers that offer a minimum of 300 dpi for best results.

Another key feature is the printing speed. Businesses can't afford to waste time. A printer that produces labels quickly can enhance efficiency. Aim for a device that can print at least 5 inches per second. This will help keep your operations running smoothly.

Tips: Pay attention to connectivity options too. Printers that support multiple connections can integrate easily into various systems. Also, consider the label size compatibility. Different products require different sizes. Not all printers handle all label sizes seamlessly. Flexibility in label formats can save you from future headaches.

Don't overlook the importance of software compatibility. A user-friendly software interface can simplify label design. Check if the printer is compatible with popular design tools. Streamlining this process can make a difference. Inconsistencies in software might lead to frustration. Keep this in mind during your selection process.

2026 Texas Label Printers Comparison

Industry Trends: The Future of Label Printing Technology

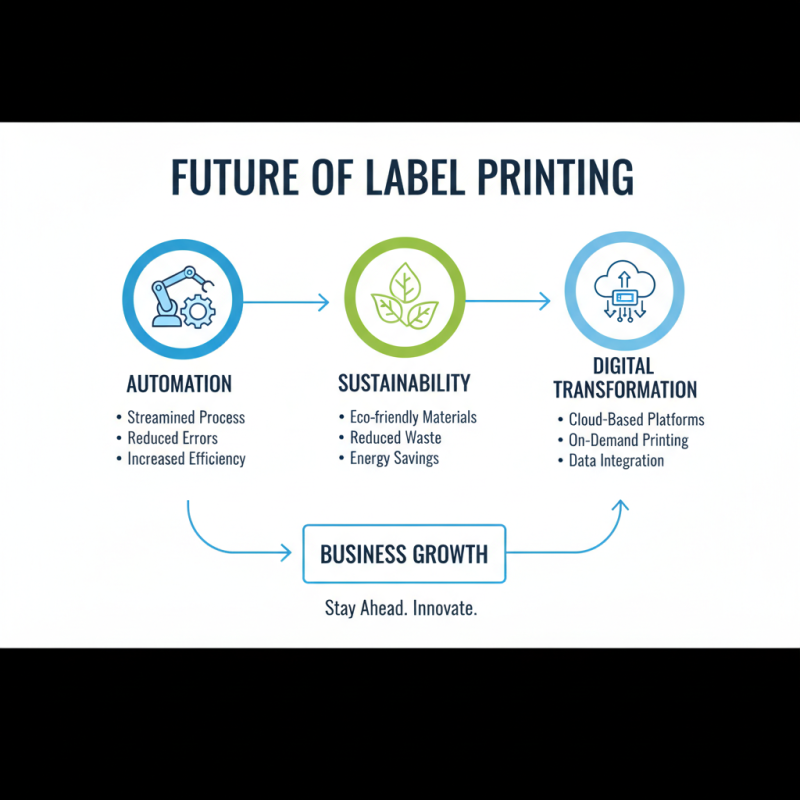

As label printing technology evolves, businesses must stay ahead. The future lies in automation, sustainability, and digital transformations. Automated systems streamline the printing process. They reduce errors and increase efficiency, allowing businesses to focus on growth.

However, adapting to new technologies can be challenging. Training staff on advanced systems can take time. Investing in user-friendly solutions can minimize this transition period. Look for printers with intuitive interfaces. This can enhance productivity without overwhelming employees.

Sustainability is also a key trend. Eco-friendly materials are becoming more accessible. Businesses are shifting towards recyclable and biodegradable options. This shift not only helps the planet but also appeals to environmentally conscious consumers.

Tips: Evaluate your current label needs before choosing a printer. Consider the volume and variety of labels required. Stay informed about technological advancements. This ensures you make informed decisions. Always plan for flexibility in your labeling processes. This can accommodate future changes in demand or design.

Related Posts

-

How to Choose the Best Label Printing Companies for Your Business Needs

-

Top 2025 Label Printers Features to Consider for Your Business Needs

-

2025 Top 5 Roll Labels for Your Business Needs and Creative Projects

-

Top 10 Creative Bottle Labels Ideas to Elevate Your Product Presentation

-

Top 10 Label Maker Machines for Home and Office: Ultimate Buying Guide

-

How to Choose the Best Bartender Label Software for Your Business Needs